ABSTRACT

A full scope training simulator using soft panels as graphic interface (TSG++) has been developed for Sta. Mar�a de Garo�a NPP. Nowadays the prototype of a complete control room panel working on Windows NT platforms with touch screens is available. Its functionality is similar to the one offered by the full scope replica simulator used by the operators. An interface by means of software elements, named soft panels, has been added for a high fidelity reproduction of the control room. Besides, a module that links the simulator with the SPDS has been developed. The simulation environment is OpenSim which allows to fulfill the ANSI 3.5 requirements. The communication between the soft-panels and the simulator is carried out by means of the TCP/IP protocol. Component technology programmed with Visual C++ is used in the development of panels elements such as indicators, switchers and so on. The simulator runs on a client/server architecture where the kernel acts as the server and the panels as clients applications. The adopted programming model allows a fast development with low resources. The availability of a simulator with these features at the plant site will improve the operators training and provide the possibility of being used for other purposes regarding its configuration flexibility.

TSG++ has been planned as a complementary tool that offers the same capabilities of a full scope replica simulator but with an interface that corresponds to the current control room. Instead of the traditional hard panel solution the interface of the new simulator will be made out of software elements, named soft panels, with a lot of derived benefits as shown later in this paper. This simulator, with full time availability at the plant site and possibility of panels distribution across the local area network, will be able to improve the operators training in an unexpensive way and, moreover, will allow its use by the rest of personnel to accomplish different tasks (control room design changes, instrumentation modifications, sequence and procedure analysis, emergency drills preparation�).

2. ARCHITECTURE OVERVIEW

The PC/Windows NT technology has increased competition and decreased cost, allowing the use of standard, off the shelf hardware and software for functions that, in the past, were performed by proprietary, specialised hardware and software. The kernel allows, in conjunction with the physical models of the reference plant, to verify the requirements included in the ANSI 3.5.

The software architecture consists of servers, a client library, clients, and an operating system interface library. Client applications normally access the various services provided by the servers contained in the client library, that is designed to allow the use of separate processes executed on different machines in a network. The operating system interface library provides a portable application interface to several process control services used in real-time applications. The use of threads allows the distribution of processes over multiple processors. To aid in the maintenance of the simulator a database manager that uses a library written to the ODBC standard and allows to use any commercial database with this driver is provided.

The components of the typical simulator configuration includes a simulator computer, a system server, the instruction station and the site network. The simulator computer has to be preferred a multiprocessor PC because it supports the real time execution of the simulator models. The system server is a PC that contains the simulator database, initial condition files, simulation model source code and instructor data files. From the instructor station the simulation models running on the simulator computer may be monitored and manipulated and instructor inputs and training scenarios may be inserted. A fast ethernet network is used for the simulator system.

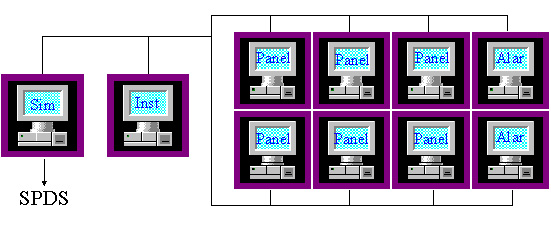

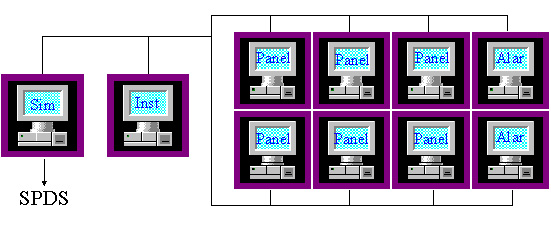

TSG++ has extended this configuration, as shown in Figure 1, with the computers where the soft panels are executed as client applications. The system server and the simulator computer are the same machine, a PC with two Pentium II processors at 400 Mhz. An special client module capable of feeding the plant SPDS with data generated by the simulator has been developed and included in the configuration.

3. SOFT PANELS INTERFACE

The interface plays a major role in this type of simulators and the configuration should allow that many users can interact with the simulation in real time. The interaction of the operators with TSG++ is carried out through several touch screens displaying high fidelity animated images of the elements in the control room (hard panels) during the operation. These screens are named soft panels. The last advances in object oriented software development simplifies the fast construction of this kind of applications. The scale of the images is tried to be constant comparing with reality. In the prototype it was used a scale of 40~45%. This size is intended to avoid the necessity of navigation through the panels or its elements, i.e, all the panels and its components are visible while the simulator is running and accessible by a single touch on the screen.

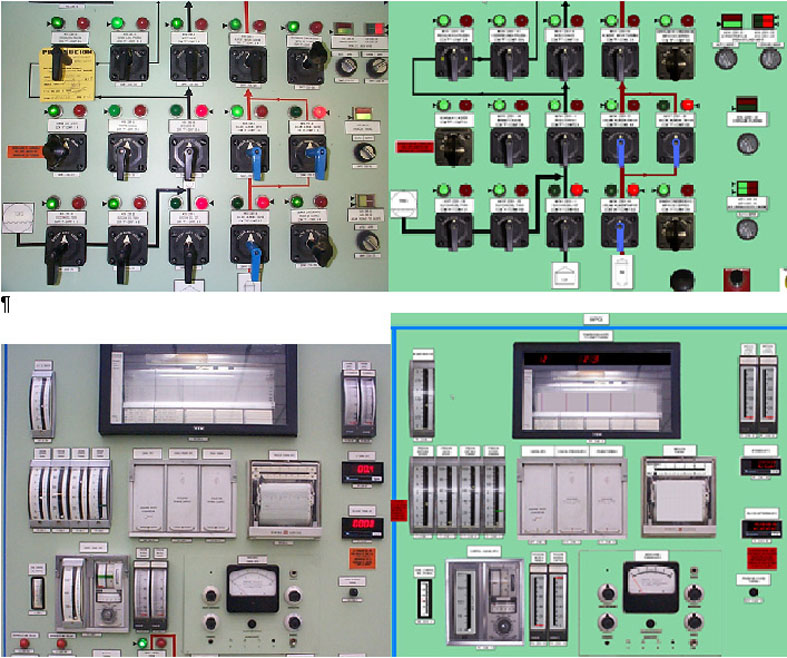

The first step during the design was the

identification and classification of the current objects in the layouts of the

hard panels. Basically, they can be of two types: switches and indicators. Then

it was specified the functionality and properties of each object. The

development of the soft panels was performed using ActiveX components

technology. Due to the specific features of the switches, they were programmed

with Visual C++ as independent client applications capable of communicating

directly with the simulator. Also the lamps were developed to incorporate this

capacity. The rest of the components were acquired from third party

vendors.

With these components it is possible to

reproduce easily and quickly the panels of the control room. These include

elements such as gauges (linear and angular), sliders, selectors, knobs, leds,

odometers, switches and buttons. Figure 2 shows a comparison between a part of a

real panel and the corresponding soft panel. They can show different images and

play sounds as resources of the simulated component. In the case of our

customized components, such us switches, they can be linked to a signal in the

same way a real object is wired in the back side of the panel. The connection of

the other components with the simulator is performed by its container

application, i.e. the corresponding soft panel. This technology has been also

applied to the development of configurable alarms panels which reproduce the

full logic and functionality of the real ones.

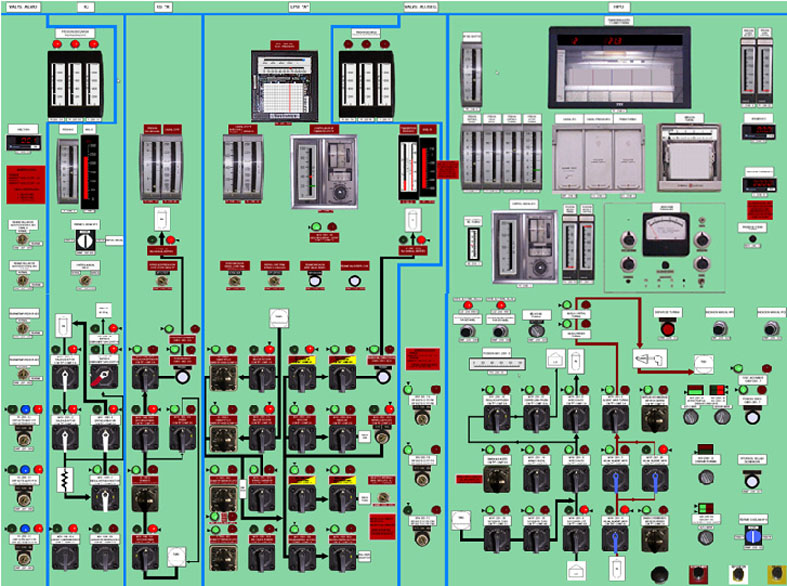

In order to test the users response to this kind of interface, a

prototype of a full panel has been implemented. With this panel the operator is

able to control the ECCS. It consists of eight touch screens displaying switches

and indicators, two alarms panels and two SPDS monitors. Figure 3 shows a

composition image of four of these panels and Figure 4 shows the entire

prototype of the same panel during a simulation.

4. CONCLUSIONS

A training simulator using soft panels (TSG++) has been developed for Santa Mar�a de Garo�a NPP. The soft panels interface design approach represents a solution which is economical both in cost and in effort in the development of the application. Apart from its suitability to be used as a training tool, this kind of interface increases the flexibility of the use of the simulator. For instance design changes in the control room can be proposed and tested with the simulator before its implantation, getting the approval of operators. Moreover, the possibility of distribution across the local area network simplifies its use by different departments.

5. MORE PHOTOS

![[First Prototype]](proto1.jpg)

![[Full Prototype]](proto2.jpg)

![[Instalation 1]](inst1.jpg)

![[Instalation 2]](inst2.jpg)

![[Training Session]](simulador.jpg)

![[Training Session]](simulador1.jpg)

![[Training Session]](simulador2.jpg)

![[Training Session]](simulador3.jpg)

![[Training Session]](simulador5.jpg)

![[Training Session]](simulador6.jpg)

Comments

to Pedro Corcuera:

corcuerp@unican.es

Comments

to Pedro Corcuera:

corcuerp@unican.es